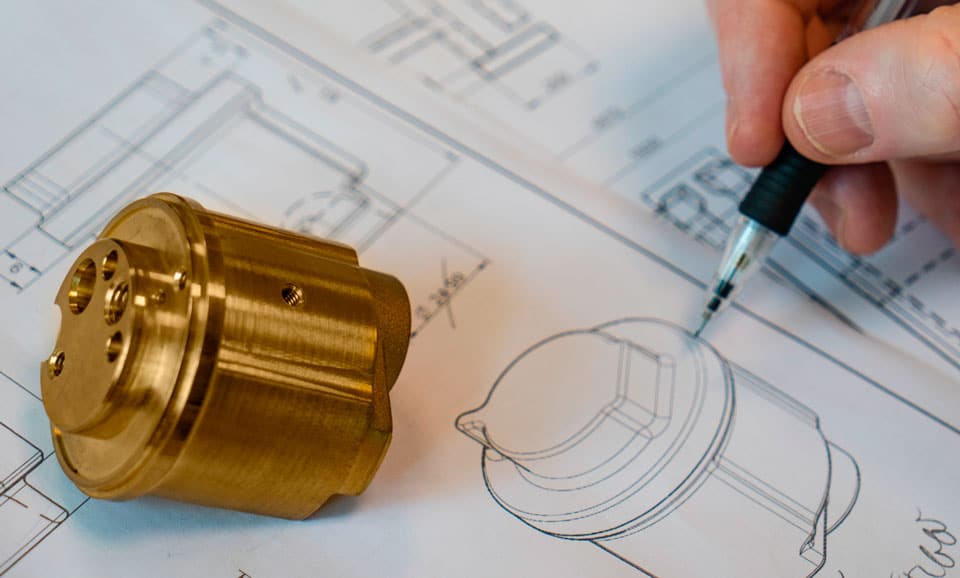

PRODUCTION PROCESS

Nuova Menon specialises in metal and hot stamping by hot forging brass, aluminum, copper and steel as well as precision mechanical machining.

The company carries out the entire production cycle in-house, taking care of the design and construction the equipment, hot forging, heat treatments, processing and surface treatments, galvanised finishes and assembly, right up to final testing.