Design, prototyping and engineering

The technical office is the beating heart of the Nuova Menon production system. It deals with the 3D design of all components processed and, employs the latest generation of CAM software to program the tool paths for making the equipment. Right from the design phase, the Technical office is also actively involved in implementing and managing the Quality Policy. Lastly, it is able to issue any FMEA (Failure Mode and Effect Analysis) and PPAP (Production Part Approval Process) documentation requested by the customer.

Latest generation highly automated software

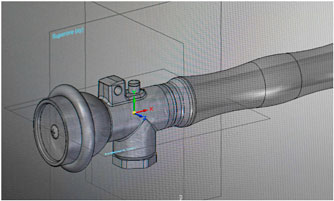

CAD 3D

The design phase makes use of 3D CAD software (Solid Edge) able to interactively and automatically analyse the project variables and to proceed easily with complex modifications and simultaneous updates.

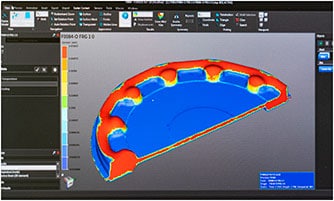

CAE

Nuova Menon is one of the few Italian companies to use Forge, the best CAE software for simulating forging. The program makes it possible to keep production launch times to the minimum and to simulate different production solutions for carrying out the process and making moulds.

CAM

CAM software programs (PoweMILL and FeatureCAM) interface the 3D design virtual geometric model with the computerised numerical control machines (CNC) used for production and give them the instructions per following the correct “tool path”.